-

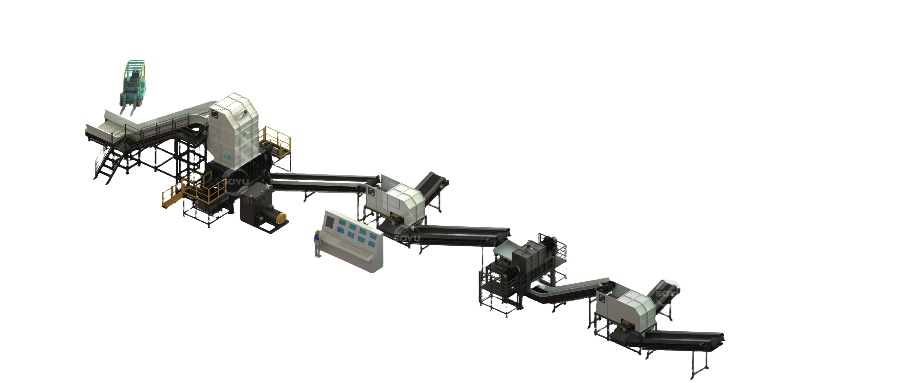

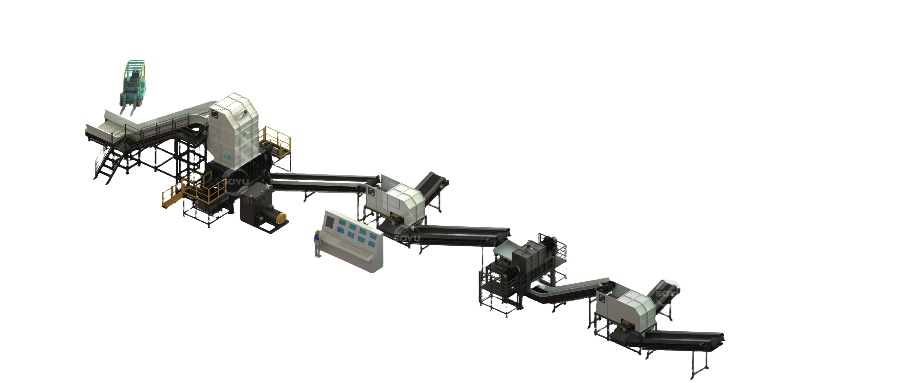

- Primary shredder

The primary shredder adopts the hydraulic system with German Linde plunger pump as the core, and the output speed and torque can be automatically adjusted. Special designed feeding device can handle pressed metal. The patented design screen makes the discharge size controllable.

-

Intelligent control system

The intelligent control system can reliably control the operation of the equipment, realize the intelligent control of the load balance of the crusher host system, improve the automatic and intelligent level of the production line operation, and reduce the working intensity of the workers. The monitoring system realizes real-time monitoring of key parameters of equipment operation, transmits data to the control center, and provides operators with real-time and reilable production line operation status.

-

Secondary shredder

The secondary shredder is optimized with a special shear structure and powerful power configuration makes it suitable for complex and variable operating conditions and improve shredding efficiency. The blade is made of high-quality imported wear-re-sistant material through multiple processing processes. The surfacing welding repair process can reduce the blade use cost.

-

-

- Sorting device

Uniformly transport the front-end processed material to the next process, and separate the magnetic materials in the nonferrous metal.

-

Special shear structure optimization to improve crushing efficiency.

The blade is made of high-quality imported wear-resistant materials and processed by multiple processes. The surfacing repair process can| reduce the blade using cost.

The strong power configuration makes the equipment suitable for complex and changeable operating conditions.

- The intelligent control system can reliably control the operation of the equipment, realize the intelligent control of the load balance of the crusher host system, improve the automatic and intelligent level of the production line operation, and reduce the working intensity of the workers. The monitoring system realizes real-time monitoring of key parameters of equipment operation, transmits data to the control center, and provides operators with real-time and reliable production line operation status.

|