Application of single shaft shredder in the scrap metal industry

Views : 7064

Update time : 2024-11-21 15:10:28

In the scrap metal recycling industry, single shaft shredder can effectively crush and separate scrap metal. By shredding large metal items such as scrap cars, home appliances, wires, etc., the single-shaft shredder can break them into smaller pieces for subsequent smelting and reprocessing.

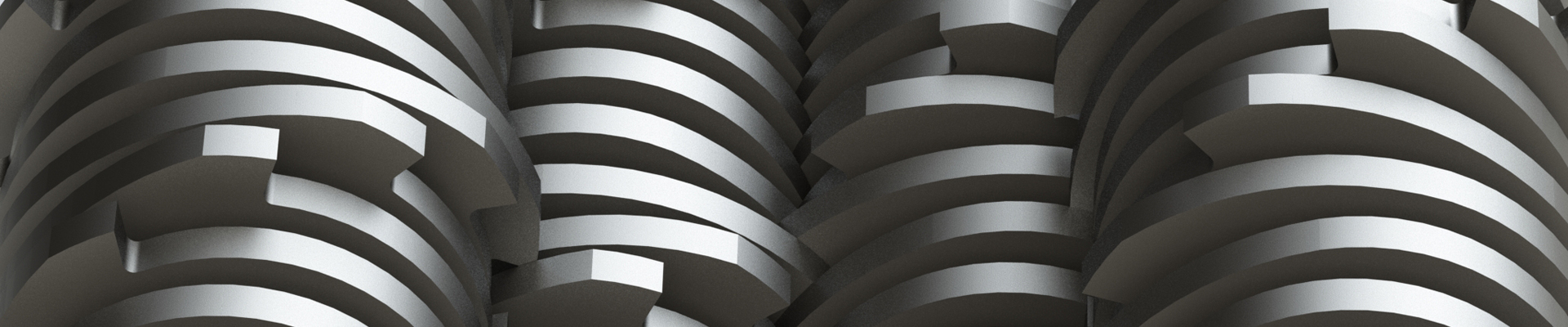

The working principle of the single shaft shredder is relatively simple and efficient. Materials (such as scrap metal) are first fed into the crushing chamber of the shredder, and then the single-shaft rotating blades are driven by the motor to cut and tear the materials. The interaction between the blades and the fixed knives on the box, as well as the high-speed rotation of the blades, makes the material be effectively broken into small pieces. The torn material particles are discharged through the screen, and the size of the discharged particles can be controlled by the aperture of the screen.

The working principle of the single shaft shredder is relatively simple and efficient. Materials (such as scrap metal) are first fed into the crushing chamber of the shredder, and then the single-shaft rotating blades are driven by the motor to cut and tear the materials. The interaction between the blades and the fixed knives on the box, as well as the high-speed rotation of the blades, makes the material be effectively broken into small pieces. The torn material particles are discharged through the screen, and the size of the discharged particles can be controlled by the aperture of the screen.

The smaller size of the shredded pieces of the single-shaft shredder helps the scrap metal to be more fully smelted and reused in the subsequent processing.

The smaller size of the shredded pieces of the single-shaft shredder helps the scrap metal to be more fully smelted and reused in the subsequent processing.

Single-shaft shredders have a powerful shredding capacity and can quickly break scrap metal into smaller pieces, thereby increasing processing efficiency.

Single-shaft shredders are usually equipped with an advanced intelligent control system, which can be automatically adjusted according to the characteristics of different materials to ensure the best shredding effect. At the same time, it is easy to operate, reducing the difficulty of operation and labour costs.

The single-shaft shredder is equipped with reliable safety protection measures, such as preventing clogging automatic shutdown and other functions, effectively avoiding potential safety hazards. In addition, through the shredding process, the volume of scrap metal has been significantly reduced, reducing the impact on the environment, in line with environmental requirements.  Through the processing of single-shaft shredder, scrap metal can be recycled and reused more effectively, thus improving the recovery rate of resources.

Through the processing of single-shaft shredder, scrap metal can be recycled and reused more effectively, thus improving the recovery rate of resources.

After shredding, scrap metal can be more convenient for subsequent smelting and processing, reducing production costs.

The recycling and reuse of scrap metal helps to reduce the demand for new metal resources, thus promoting the green transformation and sustainable development of the economy.  In summary, the application of single-shaft shredder in the scrap metal industry has significant advantages and benefits. Through the reasonable use of single-shaft shredder, the scrap metal industry can improve the recovery rate of resources, reduce production costs and promote the green transformation of the economy.

In summary, the application of single-shaft shredder in the scrap metal industry has significant advantages and benefits. Through the reasonable use of single-shaft shredder, the scrap metal industry can improve the recovery rate of resources, reduce production costs and promote the green transformation of the economy.

Single-shaft shredders have a powerful shredding capacity and can quickly break scrap metal into smaller pieces, thereby increasing processing efficiency.

Single-shaft shredders are usually equipped with an advanced intelligent control system, which can be automatically adjusted according to the characteristics of different materials to ensure the best shredding effect. At the same time, it is easy to operate, reducing the difficulty of operation and labour costs.

The single-shaft shredder is equipped with reliable safety protection measures, such as preventing clogging automatic shutdown and other functions, effectively avoiding potential safety hazards. In addition, through the shredding process, the volume of scrap metal has been significantly reduced, reducing the impact on the environment, in line with environmental requirements.

After shredding, scrap metal can be more convenient for subsequent smelting and processing, reducing production costs.

The recycling and reuse of scrap metal helps to reduce the demand for new metal resources, thus promoting the green transformation and sustainable development of the economy.