Application of bulky waste shredding and sorting equipment?

Views : 7199

Update time : 2024-11-25 10:27:56

Bulky waste shredding and sorting equipment plays an important role in modern municipal waste treatment, and its application is mainly reflected in the following aspects:

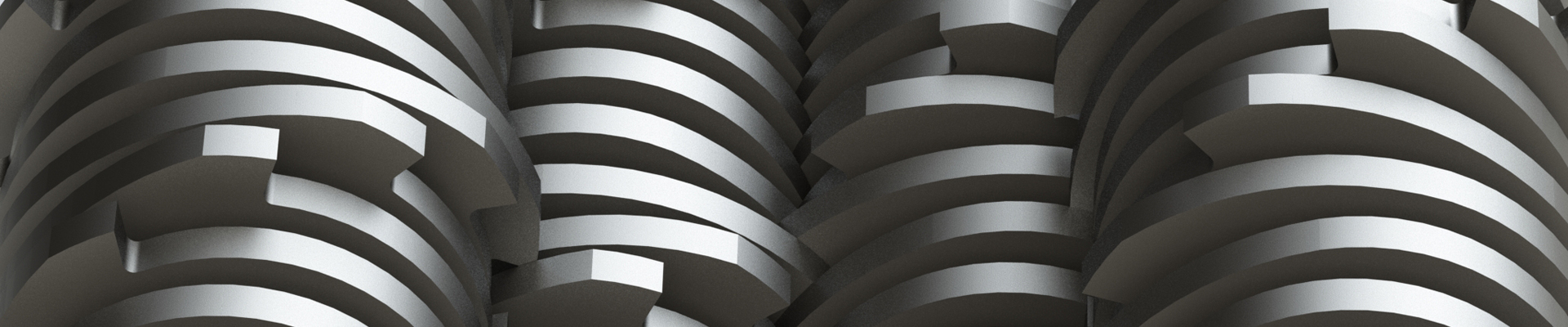

The equipment is specially designed to deal with bulky rubbish such as mattresses, sofas, furniture, waste building materials, waste wood and electrical appliances. These wastes are often large in size and complex in structure, which are not easy to be sorted and transported directly. Through the crushing function, the equipment is able to crush the bulky waste into smaller pieces or granules, which is convenient for subsequent sorting and compression processing. Crushing equipment is usually made of high-strength, wear-resistant materials with strong crushing capacity and good durability. Sorting function is one of the core functions of bulky waste crushing and sorting equipment. After the crushing process, the recyclables, hazardous materials and non-recyclables are separated by the sorting equipment. The sorting equipment usually adopts a variety of technical means such as magnetic separation, wind selection, screening and so on:

Sorting function is one of the core functions of bulky waste crushing and sorting equipment. After the crushing process, the recyclables, hazardous materials and non-recyclables are separated by the sorting equipment. The sorting equipment usually adopts a variety of technical means such as magnetic separation, wind selection, screening and so on:

They are mainly used for separating ferromagnetic materials; separating materials according to their density differences; and separating materials according to their particle size by means of screens. The combined use of these technical means can achieve efficient sorting of bulky waste and improve the resource recycling rate. For example, recyclables such as metals, plastics and wood can be separated for recycling.

The combined use of these technical means can achieve efficient sorting of bulky waste and improve the resource recycling rate. For example, recyclables such as metals, plastics and wood can be separated for recycling.

The compression function is another important function of the bulky waste crushing and sorting equipment. Recyclables and hazardous materials after sorting need to be compressed to reduce their size and facilitate transport and storage. The compression equipment usually adopts hydraulic or mechanical compression to compress the materials into compact blocks or cakes. This not only facilitates transport and storage, but also reduces processing costs and improves processing efficiency. The application of bulky waste crushing and sorting equipment is also reflected in its environmental protection and energy saving. The equipment adopts a negative pressure dust removal system during processing, which effectively reduces dust pollution and improves the operating environment. At the same time, through the recycling of resources and environmental protection, it reduces energy consumption and environmental pollution, in line with the concept of sustainable development.

The application of bulky waste crushing and sorting equipment is also reflected in its environmental protection and energy saving. The equipment adopts a negative pressure dust removal system during processing, which effectively reduces dust pollution and improves the operating environment. At the same time, through the recycling of resources and environmental protection, it reduces energy consumption and environmental pollution, in line with the concept of sustainable development.

To sum up, the application of bulky waste crushing and sorting equipment not only solves the problem of bulky waste disposal, but also realises the recycling of resources and the protection of the environment. With the continuous improvement of China's environmental awareness and the acceleration of urbanisation, the application of bulky waste crushing and sorting equipment will have a broader prospect.

The equipment is specially designed to deal with bulky rubbish such as mattresses, sofas, furniture, waste building materials, waste wood and electrical appliances. These wastes are often large in size and complex in structure, which are not easy to be sorted and transported directly. Through the crushing function, the equipment is able to crush the bulky waste into smaller pieces or granules, which is convenient for subsequent sorting and compression processing. Crushing equipment is usually made of high-strength, wear-resistant materials with strong crushing capacity and good durability.

They are mainly used for separating ferromagnetic materials; separating materials according to their density differences; and separating materials according to their particle size by means of screens.

The compression function is another important function of the bulky waste crushing and sorting equipment. Recyclables and hazardous materials after sorting need to be compressed to reduce their size and facilitate transport and storage. The compression equipment usually adopts hydraulic or mechanical compression to compress the materials into compact blocks or cakes. This not only facilitates transport and storage, but also reduces processing costs and improves processing efficiency.

Compared with the traditional manual sorting, the bulky waste crushing and sorting equipment has the characteristics of automation and intelligence. The equipment is easy to operate, and only a small number of staff can complete the entire processing, reducing labour costs. At the same time, the automated processing of the equipment greatly improves the processing efficiency, making the processing of bulky waste faster and more convenient.

To sum up, the application of bulky waste crushing and sorting equipment not only solves the problem of bulky waste disposal, but also realises the recycling of resources and the protection of the environment. With the continuous improvement of China's environmental awareness and the acceleration of urbanisation, the application of bulky waste crushing and sorting equipment will have a broader prospect.