Application of four-shaft shredder in plastic industry

Views : 7415

Update time : 2024-11-12 12:54:56

As an important equipment in the field of modern plastics recycling and processing, four-axis shredder plays an important role in the plastics industry by virtue of its powerful crushing capacity and wide range of applications. In this article, we will introduce in detail the application of four-axis shredder in waste plastics crushing, packaging plastics processing, plastic film crushing, plastic products resourcefulness, plastic waste reuse, plastic drum crushing and recycling, efficient crushing of plastic bottles as well as pre-treatment of polyester filament yarn.

1. Waste plastic crushing

1. Waste plastic crushing

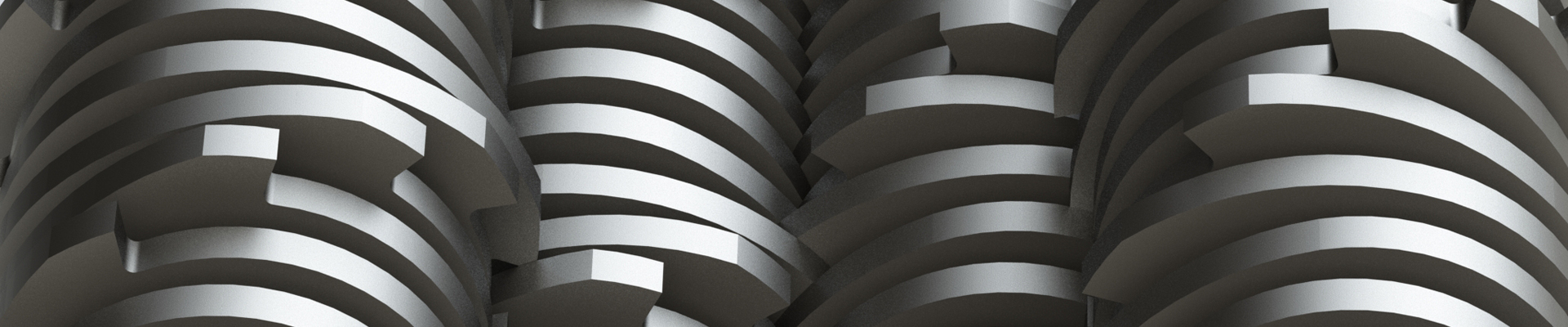

The four-axis shredder is excellent in waste plastic crushing. It is equipped with four sets of rotary cutting blades inside, which cooperate with each other through differential rotation to grab, shear and tear the waste plastics, so that they are quickly crushed into small pieces. This efficient crushing capacity not only improves the working efficiency, but also reduces the processing cost, which facilitates the subsequent recycling of plastics.

2. Packaging plastics processing

Packaging plastics, such as plastic film, plastic bags, etc., are common waste in daily life. Through advanced shredding technology, the four-axis shredder can quickly process a large amount of packaging plastics and break them into smaller pieces for subsequent recycling and reuse. This not only helps reduce environmental pollution, but also achieves effective use of resources.  3. Plastic film shredding

3. Plastic film shredding

Plastic film, such as courier bags, agricultural film, etc., is difficult to handle due to its thin and easily tangled characteristics. However, four-axis shredder with its strong crushing ability, can easily cope with a variety of thickness and material of plastic film, crushed into small uniform pieces, for subsequent processing and reuse to provide a convenient.

4. Resourcefulness of plastic products

Plastic products, such as plastic frames, plastic boards, plastic jars, etc., are often difficult to dispose of after being discarded. The four-axis shredder facilitates the subsequent cleaning and granulation processes by crushing them into small pieces, thus realising the resourceful use of plastic products. This not only helps to reduce the waste of resources, but also reduces environmental pollution.  5. Plastic waste reuse

5. Plastic waste reuse

Plastic waste is an important part of municipal waste. The four-axis shredder facilitates subsequent recycling and reuse by crushing it into smaller pieces. This not only helps to reduce environmental pollution caused by landfill and incineration, but also realises the recycling of resources and promotes sustainable development.

6. Plastic drum crushing and recycling

Plastic drums, such as paint drums and chemical drums, have always been a problem in the recycling field due to their large size and difficulty in disposal. However, the four-axis shredder, through its powerful crushing capacity, can easily break plastic buckets into small pieces, which is convenient for subsequent cleaning, granulation and other processes, thus achieving the crushing and recycling of plastic buckets and reuse.  7. Efficient Crushing of Plastic Bottles

7. Efficient Crushing of Plastic Bottles

Plastic bottles are one of the common wastes in daily life. Through its efficient crushing capacity, the four-axis shredder can quickly crush plastic bottles into small pieces, which is convenient for subsequent cleaning, granulation and other processes. This not only improves the recycling rate of plastic bottles, but also helps reduce environmental pollution.

8. Polyester filament pretreatment

Polyester filament is an important synthetic fibre raw material, and the waste generated during its production is often difficult to handle. However, the four-shaft shredder facilitates subsequent recycling and reuse by crushing it into smaller pieces. This not only helps to reduce the waste of resources, but also reduces environmental pollution and realises the green production of polyester filament yarn.  In summary, the four-shaft shredder has a wide range of application prospects in the plastics industry. Through its efficient crushing capacity and wide range of applications, the four-shaft shredder not only helps to reduce environmental pollution and resource waste, but also promotes the sustainable development of the plastics industry. With the continuous progress of technology and application expansion, the four-axis shredder will play a more important role in the plastics industry.

In summary, the four-shaft shredder has a wide range of application prospects in the plastics industry. Through its efficient crushing capacity and wide range of applications, the four-shaft shredder not only helps to reduce environmental pollution and resource waste, but also promotes the sustainable development of the plastics industry. With the continuous progress of technology and application expansion, the four-axis shredder will play a more important role in the plastics industry.

The four-axis shredder is excellent in waste plastic crushing. It is equipped with four sets of rotary cutting blades inside, which cooperate with each other through differential rotation to grab, shear and tear the waste plastics, so that they are quickly crushed into small pieces. This efficient crushing capacity not only improves the working efficiency, but also reduces the processing cost, which facilitates the subsequent recycling of plastics.

2. Packaging plastics processing

Packaging plastics, such as plastic film, plastic bags, etc., are common waste in daily life. Through advanced shredding technology, the four-axis shredder can quickly process a large amount of packaging plastics and break them into smaller pieces for subsequent recycling and reuse. This not only helps reduce environmental pollution, but also achieves effective use of resources.

Plastic film, such as courier bags, agricultural film, etc., is difficult to handle due to its thin and easily tangled characteristics. However, four-axis shredder with its strong crushing ability, can easily cope with a variety of thickness and material of plastic film, crushed into small uniform pieces, for subsequent processing and reuse to provide a convenient.

4. Resourcefulness of plastic products

Plastic products, such as plastic frames, plastic boards, plastic jars, etc., are often difficult to dispose of after being discarded. The four-axis shredder facilitates the subsequent cleaning and granulation processes by crushing them into small pieces, thus realising the resourceful use of plastic products. This not only helps to reduce the waste of resources, but also reduces environmental pollution.

Plastic waste is an important part of municipal waste. The four-axis shredder facilitates subsequent recycling and reuse by crushing it into smaller pieces. This not only helps to reduce environmental pollution caused by landfill and incineration, but also realises the recycling of resources and promotes sustainable development.

6. Plastic drum crushing and recycling

Plastic drums, such as paint drums and chemical drums, have always been a problem in the recycling field due to their large size and difficulty in disposal. However, the four-axis shredder, through its powerful crushing capacity, can easily break plastic buckets into small pieces, which is convenient for subsequent cleaning, granulation and other processes, thus achieving the crushing and recycling of plastic buckets and reuse.

Plastic bottles are one of the common wastes in daily life. Through its efficient crushing capacity, the four-axis shredder can quickly crush plastic bottles into small pieces, which is convenient for subsequent cleaning, granulation and other processes. This not only improves the recycling rate of plastic bottles, but also helps reduce environmental pollution.

8. Polyester filament pretreatment

Polyester filament is an important synthetic fibre raw material, and the waste generated during its production is often difficult to handle. However, the four-shaft shredder facilitates subsequent recycling and reuse by crushing it into smaller pieces. This not only helps to reduce the waste of resources, but also reduces environmental pollution and realises the green production of polyester filament yarn.