Features of straw shredder

Views : 7363

Update time : 2024-11-05 15:06:24

As a mechanical equipment specially designed for processing biomass materials such as straw, the straw shredder has a series of significant features. The following is a summary of the main features of the straw shredder:

First, low rotational speed of the knife shaft

First, low rotational speed of the knife shaft

Straw shredder knife shaft speed is relatively low, which helps to reduce the friction and wear generated by the equipment in operation, but also helps to better adapt to the characteristics of straw and other biomass materials, to ensure the stability and continuity of the crushing process. The low rotational speed design also helps to reduce the noise and energy consumption of the equipment and improve the overall performance of the equipment.

Second, low noise and energy consumption

The noise generated by the straw shredder in the operation process is relatively low, and will not cause much interference to the surrounding environment. At the same time, the energy consumption of the equipment is also low, in line with the modern green, energy-saving production concept. This helps to reduce the operating costs of enterprises and improve economic efficiency. Third, good reproducibility and low pollution

Third, good reproducibility and low pollution

The straw shredder has good reproducibility, i.e., the straw crushed each time has uniform particle size and stable quality. This helps to ensure the combustion efficiency and calorific value of the subsequent biomass fuel. At the same time, the equipment produces less waste during operation, which has less impact on the environment and meets the requirements of environmental protection. Fourth, stable performance, large processing capacity

Fourth, stable performance, large processing capacity

The straw shredder adopts advanced crushing technology and stable transmission system to ensure the stable and reliable performance of the equipment in the long run. At the same time, the equipment has a large processing capacity, can meet the needs of large-scale straw processing, improve the production efficiency of enterprises.

Fifth, high efficiency, energy saving

Straw shredder in the design of the full consideration of the balance between efficiency and energy saving. By optimising the structure of the crushing chamber and the layout of the cutting tool, to improve the crushing efficiency; at the same time, the use of advanced energy-saving technology to reduce the energy consumption of the equipment in the process of operation, to achieve high efficiency and energy-saving production goals.

Sixth, simple and convenient maintenance

The structure of the straw shredder is reasonably designed, simple and convenient maintenance. The key components of the equipment are easy to disassemble and replace, reducing maintenance costs. In addition, the equipment has a high degree of intelligence, with automatic monitoring and fault diagnosis function, can be found in time and solve the problem, to ensure the normal operation of the equipment. Seven, the design of patented knives

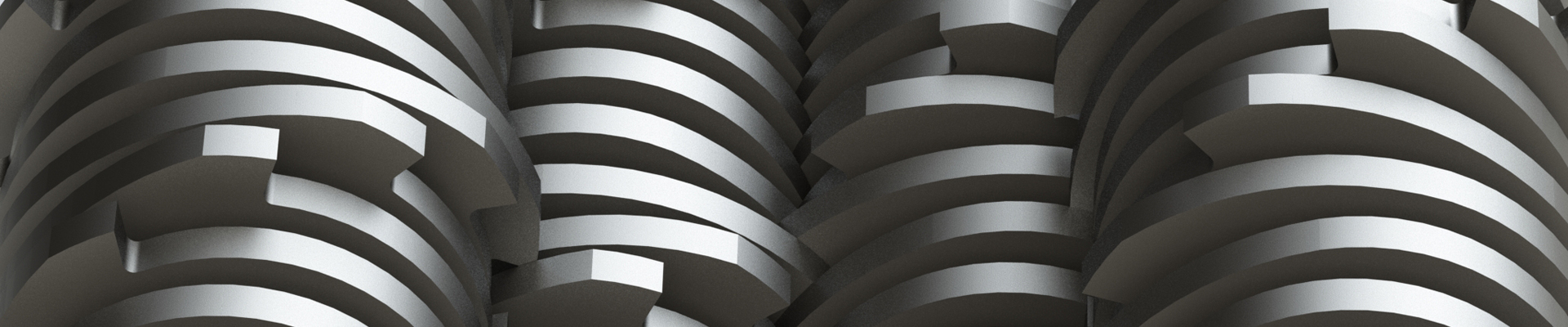

Seven, the design of patented knives

Straw shredder with a design patent knife, these knives have wear-resistant, corrosion-resistant, high hardness advantages. In the crushing process, the knife can maintain a sharp edge, improve crushing efficiency and quality. At the same time, the use of patented knives also reduces the maintenance frequency and cost of the equipment. Eight, a wide range of applications

Eight, a wide range of applications

The straw shredder is not only suitable for the crushing and processing of crops such as straw, but also can be used for the crushing and processing of a variety of materials such as wood, plastic and so on. This makes it has a wide range of applications and flexible application scenarios.

In summary, straw shredder plays an important role in biomass energy industry and agricultural production with its unique advantages. With the continuous progress of technology and the continuous development of the market, it is believed that the straw shredder will play a more important role in the future, contributing more power to the development of biomass energy industry and the progress of agricultural production.

Straw shredder knife shaft speed is relatively low, which helps to reduce the friction and wear generated by the equipment in operation, but also helps to better adapt to the characteristics of straw and other biomass materials, to ensure the stability and continuity of the crushing process. The low rotational speed design also helps to reduce the noise and energy consumption of the equipment and improve the overall performance of the equipment.

Second, low noise and energy consumption

The noise generated by the straw shredder in the operation process is relatively low, and will not cause much interference to the surrounding environment. At the same time, the energy consumption of the equipment is also low, in line with the modern green, energy-saving production concept. This helps to reduce the operating costs of enterprises and improve economic efficiency.

The straw shredder has good reproducibility, i.e., the straw crushed each time has uniform particle size and stable quality. This helps to ensure the combustion efficiency and calorific value of the subsequent biomass fuel. At the same time, the equipment produces less waste during operation, which has less impact on the environment and meets the requirements of environmental protection.

The straw shredder adopts advanced crushing technology and stable transmission system to ensure the stable and reliable performance of the equipment in the long run. At the same time, the equipment has a large processing capacity, can meet the needs of large-scale straw processing, improve the production efficiency of enterprises.

Fifth, high efficiency, energy saving

Straw shredder in the design of the full consideration of the balance between efficiency and energy saving. By optimising the structure of the crushing chamber and the layout of the cutting tool, to improve the crushing efficiency; at the same time, the use of advanced energy-saving technology to reduce the energy consumption of the equipment in the process of operation, to achieve high efficiency and energy-saving production goals.

Sixth, simple and convenient maintenance

The structure of the straw shredder is reasonably designed, simple and convenient maintenance. The key components of the equipment are easy to disassemble and replace, reducing maintenance costs. In addition, the equipment has a high degree of intelligence, with automatic monitoring and fault diagnosis function, can be found in time and solve the problem, to ensure the normal operation of the equipment.

Straw shredder with a design patent knife, these knives have wear-resistant, corrosion-resistant, high hardness advantages. In the crushing process, the knife can maintain a sharp edge, improve crushing efficiency and quality. At the same time, the use of patented knives also reduces the maintenance frequency and cost of the equipment.

The straw shredder is not only suitable for the crushing and processing of crops such as straw, but also can be used for the crushing and processing of a variety of materials such as wood, plastic and so on. This makes it has a wide range of applications and flexible application scenarios.

In summary, straw shredder plays an important role in biomass energy industry and agricultural production with its unique advantages. With the continuous progress of technology and the continuous development of the market, it is believed that the straw shredder will play a more important role in the future, contributing more power to the development of biomass energy industry and the progress of agricultural production.