Features of the Four shaft shredder

Views : 7152

Update time : 2024-10-28 15:52:14

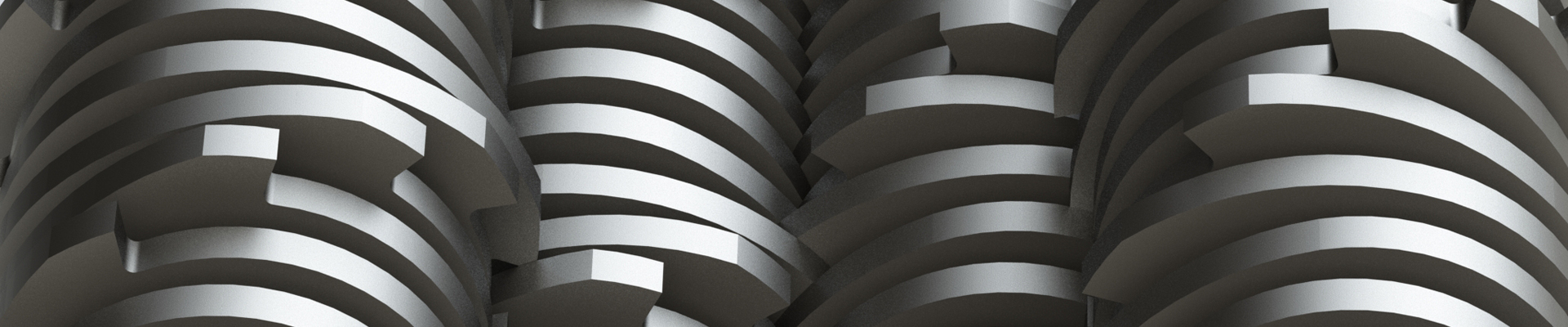

The Four shaft shredder is a versatile and universal machine whose main features can be summarised in the following aspects:

I. Structure and design

1. the crushing chamber consists of upper double auxiliary knife shafts and lower double main knife shafts, this design can provide greater shear force to effectively deal with a variety of materials.

2. Adopting standard modular design, good interchangeability of parts, convenient for maintenance and replacement. II.Performance and efficiency

II.Performance and efficiency

1. Four shaft shredder is designed with low rotational speed and large torque to ensure crushing efficiency and reduce noise. 2.

2. It can process a large amount of materials efficiently, and the size of the discharged material can be controlled, and the discharged material is even.

3. the auxiliary knives are made of moulded forging parts and the main knives are made of special alloy steel through a special process, with good wear resistance and long service life. III.Function and applicability

III.Function and applicability

1. It is suitable for shredding many kinds of materials such as plastic drums, plastic baskets, IBC drums, metal drums, metal baskets, waste paper, circuit boards, computer shells, computer mainframes, automobile bumpers, domestic rubbish, medical rubbish, hazardous wastes, electronic wastes and so on.

2. The upper auxiliary knife has the function of forced feeding, which can increase the effective crushing output of the main knife, meanwhile, the large-size materials can be brought back to the crushing chamber for repeated crushing to achieve the purpose of controlling the size of the discharged materials.

3. It comes with a screen that can be screened and quickly replaced, and the material size can be adjusted according to the aperture of the screen. IV.Intelligence and safety

IV.Intelligence and safety

1. The electrical part adopts advanced PLC programme control, with automatic overload protection function. Some models are also equipped with intelligent frequency conversion drive technology, which monitors the knife shaft and torque in real time and automatically increases or decreases the speed of the knife shaft according to the demand.

2. With multiple safety protection functions, such as overload protection, to ensure stable operation and prolong the service life of the equipment. V. Maintenance and convenience

V. Maintenance and convenience

1. Convenient maintenance and simple dismantling of screen mesh.

2. Regularly check the equipment on the connection parts of the connection is loose, the current of the main motor and the wear and tear of the knife, etc., you can keep the equipment in good operating condition.

To sum up, Four shaft shredder has significant advantages and broad application prospects in the field of solid waste treatment with its unique four-axis structure, efficient processing capacity, wide range of applications, intelligent control system and convenient maintenance.

I. Structure and design

1. the crushing chamber consists of upper double auxiliary knife shafts and lower double main knife shafts, this design can provide greater shear force to effectively deal with a variety of materials.

2. Adopting standard modular design, good interchangeability of parts, convenient for maintenance and replacement.

1. Four shaft shredder is designed with low rotational speed and large torque to ensure crushing efficiency and reduce noise. 2.

2. It can process a large amount of materials efficiently, and the size of the discharged material can be controlled, and the discharged material is even.

3. the auxiliary knives are made of moulded forging parts and the main knives are made of special alloy steel through a special process, with good wear resistance and long service life.

1. It is suitable for shredding many kinds of materials such as plastic drums, plastic baskets, IBC drums, metal drums, metal baskets, waste paper, circuit boards, computer shells, computer mainframes, automobile bumpers, domestic rubbish, medical rubbish, hazardous wastes, electronic wastes and so on.

2. The upper auxiliary knife has the function of forced feeding, which can increase the effective crushing output of the main knife, meanwhile, the large-size materials can be brought back to the crushing chamber for repeated crushing to achieve the purpose of controlling the size of the discharged materials.

3. It comes with a screen that can be screened and quickly replaced, and the material size can be adjusted according to the aperture of the screen.

1. The electrical part adopts advanced PLC programme control, with automatic overload protection function. Some models are also equipped with intelligent frequency conversion drive technology, which monitors the knife shaft and torque in real time and automatically increases or decreases the speed of the knife shaft according to the demand.

2. With multiple safety protection functions, such as overload protection, to ensure stable operation and prolong the service life of the equipment.

1. Convenient maintenance and simple dismantling of screen mesh.

2. Regularly check the equipment on the connection parts of the connection is loose, the current of the main motor and the wear and tear of the knife, etc., you can keep the equipment in good operating condition.

To sum up, Four shaft shredder has significant advantages and broad application prospects in the field of solid waste treatment with its unique four-axis structure, efficient processing capacity, wide range of applications, intelligent control system and convenient maintenance.