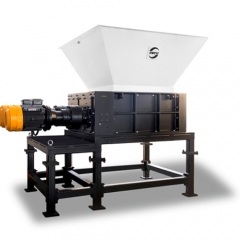

Four shaft shredder (FS100 Series)

FS100 series machines have a variety of functions and advantages. They have advantages in strong generability, standardization and modularization design, high interchangeability for their components. Their assistant blades are refined by forging and milling process and their main blades are made of special alloy steel with high strength and strong antiwear. The drive part takes advantage of gears transmission in the middle to make them rotate at different speeds. It’s convenient to disassemble the screen. Such model is of beautiful appearance and precise configuration.

They fit for shredding large and hard objects such as car body, solid industrial waste, medical waste, e-waste, plastic pail, plastic frame, plastic bottle, metal can, metal pail, intertexture bag, fridge, electric circuit board, paper box, wood and so on.

-

Applications:

-Bucket products: plastic bucket, metal drum, paint bucket, intermediate -bulk container (IBC) and dustbin

-Wastes: household waste, medical waste, kitchen waste, industrial waste, park waste

-Plastic products: plastic bottle, plastic frame, plastic block, plastic can

-Metal products: aluminum profile, oil filter, car shell, pop-top can, metal can

-Paper: newspaper, card paper, corrugated paper, copy paper

-Electronic appliances: refrigerator, circuit board, laptop shell, TV set shell, CD disk

-Glass

Electric system

| Model | Motor power | Main blade thickness | Main blade rotation diameter | Cutting chamber dimensions(mm) | Overall dimensions(LxWxH)(mm) | Weight |

| FS4030 | 1.5KW | 18.5mm | φ180mm | 400x300mm | 850x600x1650mm | 1600kg |

| FS6650 | 7.5KW | 18.5mm | φ230mm | 660x500mm | 1600x800x1940mm | 1000kg |

| FS8040 | 2x11KW | 18.5mm | φ245mm | 800x400mm | 1940x1200x2065mm | 1600kg |

| FS8060 | 2x11KW | 800x600mm | 2130x1200x2065mm | 1800kg | ||

| FS8080 | 2x11KW | 800x800mm | 2360x1200x2065mm | 2000kg | ||

| FS9080 | 2x22KW | 25mm | φ290mm | 900x800mm | 2690x1450x2450mm | 3500kg |

| FS90100 | 2x22KW | 900x1000mm | 2890x1450x2450mm | 4200kg | ||

| FS10080 | 2x30KW | 40mm | φ320mm | 1000x800mm | 2620x1800x2500mm | 5000kg |

| FS100100 | 2x30KW | 1000x1000mm | 2820x1800x2500mm | 5500kg | ||

| FS100120 | 2x30KW | 1000x1200mm | 3020x1800x2500mm | 6000kg | ||

| FS100140 | 2x30KW | 1000x1400mm | 3220x1800x2500mm | 6500kg | ||

| FS130100 | 2x15+2x30KW | 50mm | φ430mm | 1300x1000mm | 3550x2000x3100mm | 11500kg |

| FS130120 | 2x15+2x30KW | 1300x1200mm | 3650x2000x3100mm | 12500kg | ||

| FS130140 | 2x15+2x37KW | 1300x1400mm | 3850x2000x3100mm | 13500kg | ||

| FS130180 | 2x15+2x37KW | 1300x1800mm | 4250x2000x3100mm | 15500kg | ||

| FS160140 | 2x30+2x45KW | 50mm | φ534mm | 1600x1400mm | 4160x2200x3630mm | 17000kg |

| FS160160 | 2x30+2x45KW | 1600x1600mm | 4360x2200x3630mm | 18000kg | ||

| FS160200 | 2x30+2x55KW | 1600x2000mm | 4560x2200x3630mm | 19000kg |