Single Shaft Shredder SR600Series

Single shaft shredders reduce bulky materials into small, consistent particles. The material size is reduced using a pusher system and shingle shaft rotary blades. The particle size is determined by the screen mesh hole size, ranging from 40 to 100mm.

| Application: | |

| Film | |

| Wire and cables | |

| Glass fiber | |

| Wood scrap | |

| Solid waste | |

Description

Single shaft shredder

The SR series single shaft shredder is popular size reduction machine used for materials that contain minimal amounts of metal, such as plastic, paper, wood, waste wires and cables. The screen mesh size is determined by material nature and subsequent processing requirements. The shredded particles can then be reused or further processed. An intelligent electric control provides a high degree of machine safety.

| Application: | |

| Film | |

| Wire and cables | |

| Glass fiber | |

| Wood scrap | |

| Solid waste | |

Features

Rotor

“V” arrangement rotor with double side edge cutters prevent material build up. The rotating blades are made of CrMoV high alloy wear resistant steel, with different configurations and compositions available. The cutter blades feature a long service life allowing for multiple reuse before needing to be replaced.

Adjustable fixed blade

Adjustable fixed blade: the spacing between fixed blades is adjustable to create a broader shredding range. Surface overlaying wear-resistant material is used as the fixed blade, allowing the shredder to handle harder or higher abrasion materials as well as provide long term, stable operation.

Pusher system

Pusher system: reinforced baseplate can reduce the impact caused by material entering the cutting chamber. A dust collection device is equipped at the bottom of the pusher system to guarantee the long-term stable performance of internal components.

Screen unit:

Screen unit: a wide range of screens with a variety of configurations and mesh sizes are replaceable based on customer’s production requirements. The paper shredder will automatically stop while opening the screen unit to ensure operator safety. The screen is produced and mounted in sections, allow for easy maintenance.

Drive train:

Drive train: intelligent hydraulic control. When shredding breakable materials, the oil cylinder will run at the fastest speed; when shredding difficult materials, the pushing speed will slow down to prevent rotor overloading. Every hydraulic system is equipped with a cooling system to increase the durability and stability in long-time operation.

Two different drive systems are available for various shredder models. High-power shredders are all equipped with hydraulic couplers. The safety factor of reducer is >2.0.replaced.

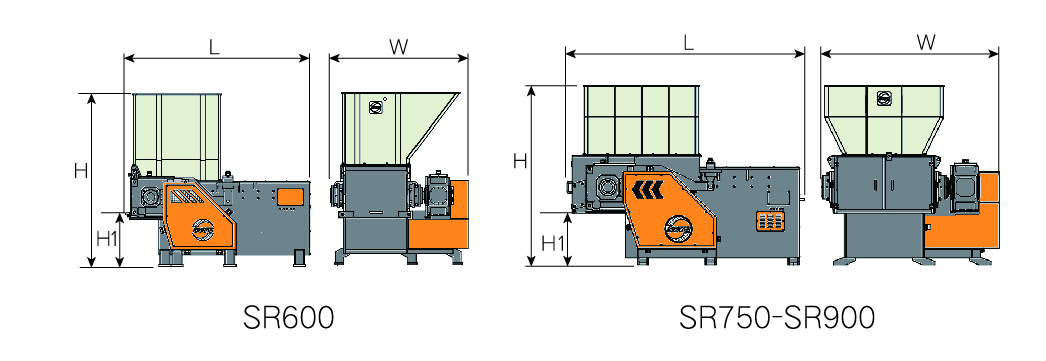

Parameters

| Model | SR600 | SR750 | SR900 | SR1400 | SR1600 | SR2100 |

|---|---|---|---|---|---|---|

| Main shaft speed(rpm) | 73 | 73 | 73 | 73 | 73 | 73 |

| Ram travel(mm) | 500 | 820 | 820 | 820 | 1000 | 1000 |

| Rotor diameter(mm) | Φ220 | Φ400 | Φ400 | Φ400 | Φ480 | Φ480 |

| Number of rotor blades(pcs) | 23 | 44 | 52 | 80 | 94 | 122 |

| Number of fixed blades(pcs) | 4 | 6 | 6 | 10 | 12 | 16 |

| Discharge height(mm) | 500 | 610 | 610 | 610 | 950 | 950 |

| Screen holes diameter(mm) | 40 | 40 | 40 | 40 | 40 | 40 |

| Motor power(kw) | 18.5 | 37 | 45 | 75~90 | 2x55~2x75 | 2x75~2x90 |

| Hydraulic power(kw) | 1.5 | 2.2 | 2.2 | 5.5 | 7.5 | 7.5 |

| Cutting chamber dimensions(mm) | 540x600 | 830x708 | 830x840 | 830x1302 | 1000x1533 | 1000x1995 |

| Overall dimensions(LxWxH)(mm) | 1800x1350x1700 | 2810x2000x2115 | 2810x2100x2115 | 2810x2890x2115 | 3475x4100x2700 | 3475x4900x2700 |

| Weight(kg) | Approx 1600 | Approx 4460 | Approx 4560 | Approx 6200 | Approx 10800 | Approx 13000 |

Cases

Related Products