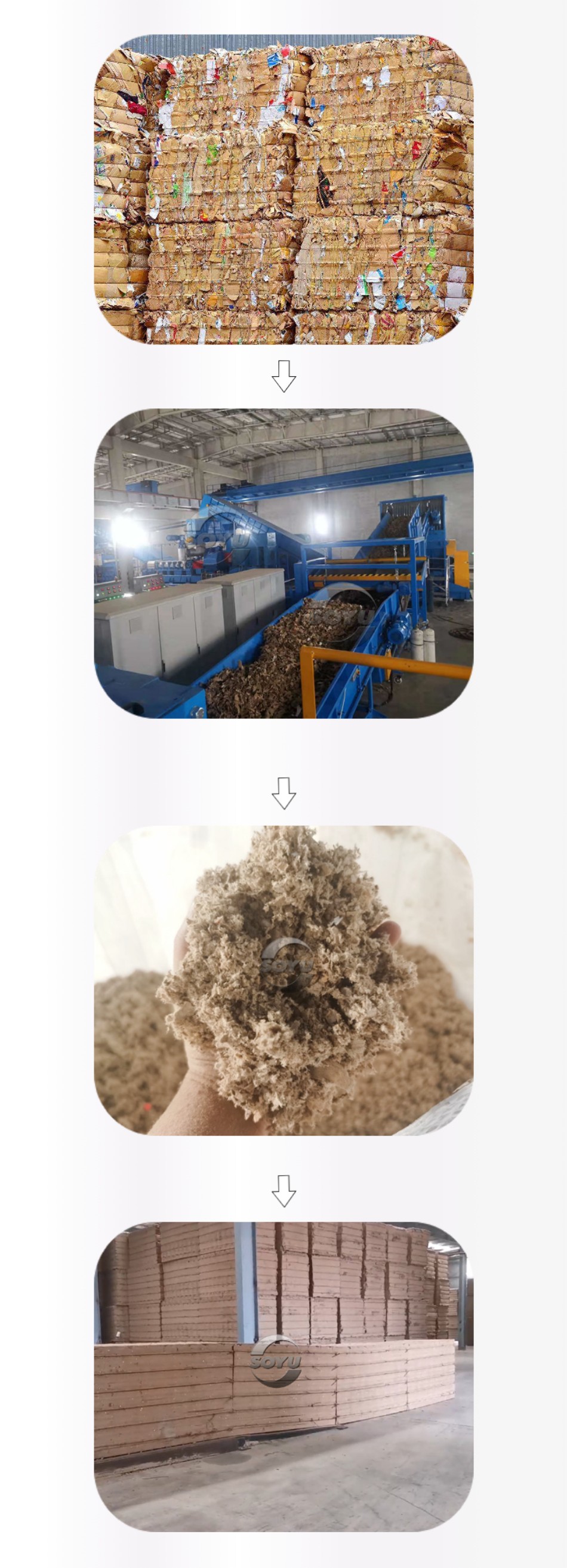

OCC Paper Dry Pulping Line

Scope of Application

Waste Paper

Comugated Paper

Paper Pipe

Corrugated paper

Cardboard

Carton

Online Inquiry

Waste Paper

Comugated Paper

Paper Pipe

Corrugated paper

Cardboard

Carton

Description

Waste paper recycling is a process of repeated papermaking, mainly recycling paper fibers in waste paper, which can greatly save resources and reduce pollutant emissions. In foreign countries, waste paper has the reputation of urban forest resources. Whether it is waste newspapers, book paper, office paper, or kraft paper, cardboard boxes, corrugated paper, etc., they are all valuable fiber raw materials used in papermaking. Using waste paper to make paper has the advantages of low energy consumption, low processing cost, low unit raw material cost, and reduced environmental pollution. Therefore, paper and cardboard produced from recycled fibers are called green products.

The waste paper shredder is a special equipment for waste paper and waste board. The unique design idea and processing technology of the waste paper shredder can make any shape of waste corrugated paper, cardboard, newspapers, waste books, cartons, paper tubes, paper tubes, cardboards. Wait for the material to be quickly processed into small pieces and collected to ensure that there is no dust.

SOYU has many successful cases and has created many high-quality waste paper crushing and dry pulp treatment equipment. Dry process waste paper pulping process waste paper dry pulping system provides a production method of waste paper dry pulp, which specifically includes the steps of waste paper pretreatment, waste paper crushing, dry pulping, pulse dust removal, strong magnetic iron removal, hydraulic packaging and so on. The production method of dry pulp is ingenious. After the processing of waste paper, it can turn waste into treasure, which is deeply loved by paper mills.

Product structure

1,Control system 2,Primary shredder Heavy-type four shaft shredder, the large shredding chamber design enables the hydraulic packaging of waste paper to realize the whole package feeding. Loose discharge provides great guarantee for the efficiency of subsequent shredding. Powerful hydraulic system with German brand Linde plunger pump as its core, with adaptive ability, can automatically adjust part of the rotation speed according to the material conditions, greatly improving the shredding efficiency. 3,Secondary shredder Heavy-type single shaft shredder have excellent performance, high speed and stable capacity It has a longitudinal shredding chamber and a larger area of pressing and pushing plate, so that more materials can contact with the blade roller at the same time. A special protection device is designed to quickly disconnect the power when encountering hard and non-shredding objects, maximize the protection of the equipment blade roller, and reduce the rate of secondary injury. The rotor blade is made of high-quality alloy steel with titanium plating, which greatly extends its service life. 4,Dust removal system The pulse structure dust removal system automatically collects the dust generated during crushing, minimizing the on-site dust, and improving the on-site cleanliness. 5,Air separation feeding device and grinding aggregate system The special negative pressure structure design can uniformly convey materials. Heavy materials can remove materials with high density through specific gravity differences. High speed rotary crushing, and the elastic screen pressing structure is convenient for maintenance and replacement of screen. After the materials are settled through the double rotating air duct structure, they are discharged and collected centrally by rotary valve 6,Fully automatic baler Adopt constant power variable hydraulic system, automatic binding, high packing density, adjustable package length, and reduced transportation costs. |

Rendering after crushing

Successful projects