Features of Aluminium Shredder

Views : 7059

Update time : 2024-11-20 10:36:12

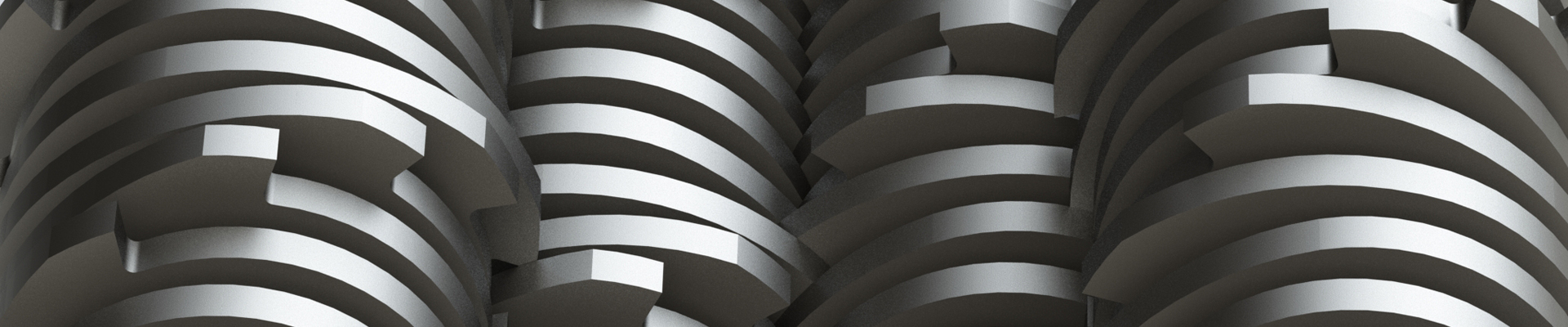

Aluminium shredder, also known as waste aluminium profile crusher, is a kind of crushing equipment designed for processing all kinds of waste aluminium alloy, aluminium profiles, broken bridge aluminium, aluminium plate, aluminium foil and so on. It is able to refine the large-size and difficult-to-crush aluminium materials with the advantages of even discharge and controllable size. Aluminium profile shredder plays an important role in the field of waste aluminium profile recycling with its high efficient crushing capacity, high durability and wear resistance, flexibility and customization, intelligent control and convenient operation, as well as energy saving and environmental protection and high efficiency.

Aluminium profile shredder is mainly composed of motor, hardened gear reducer, rotary knife shaft, imported movable knife, fixed knife, frame, seat, box, working platform and other main structures. Among them, the crushing knife is the core component, which consists of a set of fixed crushing knife and a set of movable crushing knife, through the interaction between the knives, the aluminium profile is crushed efficiently.

Aluminium profile shredder is mainly composed of motor, hardened gear reducer, rotary knife shaft, imported movable knife, fixed knife, frame, seat, box, working platform and other main structures. Among them, the crushing knife is the core component, which consists of a set of fixed crushing knife and a set of movable crushing knife, through the interaction between the knives, the aluminium profile is crushed efficiently.

The working principle of aluminium profile shredder is mainly based on physical effects such as shearing, tearing and extrusion. When the machine is in operation, the two relatively rotating knives shear and tear each other to crush the material. Aluminium profiles to be crushed are firstly fed into the machine, and through the interaction of the knives, efficient crushing treatment is achieved.

The working principle of aluminium profile shredder is mainly based on physical effects such as shearing, tearing and extrusion. When the machine is in operation, the two relatively rotating knives shear and tear each other to crush the material. Aluminium profiles to be crushed are firstly fed into the machine, and through the interaction of the knives, efficient crushing treatment is achieved.

Aluminium profile shredder has the following significant performance advantages features:

- The processing capacity depends on the model, generally ranging from 0.5 to 30 tons/hour, capable of efficiently processing all kinds of waste aluminium profiles.

- Strong power, low rotational speed, high torque, to ensure that the shredded material is uniform, finely crushed, easy to follow-up processing or transport.

- The advanced and reasonable design of the equipment, thick plate, can resist high torque, the overall structure is robust and durable, adapt to long-time high-intensity work.

- Adopting standardised modular design, good interchangeability of parts, convenient for maintenance and upgrading.

- Discharge size can be adjusted according to user requirements to meet different processing needs.

- Adopting microcomputer (PLC) automatic control, with start, stop, reverse and overload automatic reverse control function, easy to operate, safe and reliable.  Aluminium profile shredder is widely used in the field of waste recycling, which can deal with all kinds of waste aluminium materials, such as waste aluminium alloy doors and windows, waste aluminium plates, waste aluminium profiles and so on. After crushing them, they can be sorted, screened and smelted for recycling and reuse. In addition, the shredder can also be used for crushing and processing of other materials such as plastics, wood, etc., which has a wide range of application prospects.

Aluminium profile shredder is widely used in the field of waste recycling, which can deal with all kinds of waste aluminium materials, such as waste aluminium alloy doors and windows, waste aluminium plates, waste aluminium profiles and so on. After crushing them, they can be sorted, screened and smelted for recycling and reuse. In addition, the shredder can also be used for crushing and processing of other materials such as plastics, wood, etc., which has a wide range of application prospects.

Aluminium profile shredder has the following significant performance advantages features:

- The processing capacity depends on the model, generally ranging from 0.5 to 30 tons/hour, capable of efficiently processing all kinds of waste aluminium profiles.

- Strong power, low rotational speed, high torque, to ensure that the shredded material is uniform, finely crushed, easy to follow-up processing or transport.

- The advanced and reasonable design of the equipment, thick plate, can resist high torque, the overall structure is robust and durable, adapt to long-time high-intensity work.

- Adopting standardised modular design, good interchangeability of parts, convenient for maintenance and upgrading.

- Discharge size can be adjusted according to user requirements to meet different processing needs.

- Adopting microcomputer (PLC) automatic control, with start, stop, reverse and overload automatic reverse control function, easy to operate, safe and reliable.