Glass fibre shredder: a powerful tool to reshape the green cycle

Views : 7792

Update time : 2024-10-16 14:29:56

In today's increasingly environmentally conscious world, the efficient treatment of waste glass fibre has become the focus of industry attention. We are proud to introduce the latest generation of glass fibre shredders, which lead the new trend of recycling waste materials with excellent performance and innovative technology.

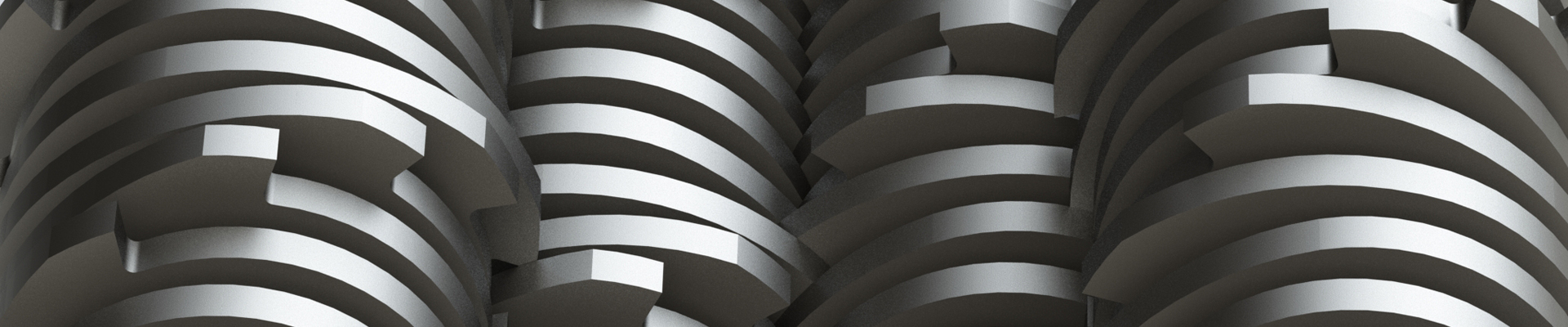

Our glass fibre shredders are made of high-strength alloy material, which is wear-resistant and corrosion-resistant, ensuring stable operation for a long time. Its unique blade design combined with a highly efficient power system can easily cope with glass fibre waste of various sizes and shapes, achieving fast and even crushing results. The technology is based on the advanced shear crushing principle, and through the interaction between the high-speed rotating disc and the fixed blades, the glass fibre is strongly sheared, torn and extruded, and finally decomposed into fine granular materials. During the process, the intelligent control system precisely adjusts the parameters to ensure the best balance between the crushing effect and energy consumption.

The technology is based on the advanced shear crushing principle, and through the interaction between the high-speed rotating disc and the fixed blades, the glass fibre is strongly sheared, torn and extruded, and finally decomposed into fine granular materials. During the process, the intelligent control system precisely adjusts the parameters to ensure the best balance between the crushing effect and energy consumption.

A large glass fibre products factory introduced our crusher, successfully achieved the reuse of waste products. It not only reduces the area occupied by the waste pile, but also reduces the production cost and improves the resource utilisation rate through the reprocessing of recycled materials. This case has attracted wide attention in the industry and become a model for waste glass fibre treatment. We are aware of the importance of environmental protection, so the concept of energy saving and emission reduction was incorporated at the beginning of the design. The shredder is driven by a low-noise, low-energy motor, which reduces the impact on the environment. At the same time, by optimising the shredding process, the purity and quality of the recycled material is improved, creating favourable conditions for subsequent reuse.

We are aware of the importance of environmental protection, so the concept of energy saving and emission reduction was incorporated at the beginning of the design. The shredder is driven by a low-noise, low-energy motor, which reduces the impact on the environment. At the same time, by optimising the shredding process, the purity and quality of the recycled material is improved, creating favourable conditions for subsequent reuse.

In order to ensure the normal operation and prolong the service life of the equipment, we provide a detailed operation manual and maintenance guide. Users only need to follow the guide to carry out daily operation and regular maintenance, you can easily master the use of equipment skills and maintenance points.

In order to ensure the normal operation and prolong the service life of the equipment, we provide a detailed operation manual and maintenance guide. Users only need to follow the guide to carry out daily operation and regular maintenance, you can easily master the use of equipment skills and maintenance points.

Since the launch of the product, we have received many positive feedback from customers. They generally said that the crusher performance is stable, easy to operate, easy to maintain, greatly improving production efficiency and economic benefits. At the same time, its environmental protection and energy saving characteristics have also won the praise of customers.

Our glass fibre shredders are made of high-strength alloy material, which is wear-resistant and corrosion-resistant, ensuring stable operation for a long time. Its unique blade design combined with a highly efficient power system can easily cope with glass fibre waste of various sizes and shapes, achieving fast and even crushing results.

A large glass fibre products factory introduced our crusher, successfully achieved the reuse of waste products. It not only reduces the area occupied by the waste pile, but also reduces the production cost and improves the resource utilisation rate through the reprocessing of recycled materials. This case has attracted wide attention in the industry and become a model for waste glass fibre treatment.

Since the launch of the product, we have received many positive feedback from customers. They generally said that the crusher performance is stable, easy to operate, easy to maintain, greatly improving production efficiency and economic benefits. At the same time, its environmental protection and energy saving characteristics have also won the praise of customers.