Shredding systems for paper mill waste: optimising production, going green first

Views : 7351

Update time : 2024-10-17 11:16:33

The disposal of light slag and strand has always been a challenge in the refined production of the paper industry. If these wastes are not properly disposed of, they not only take up space, but can also affect production efficiency and environmental quality.

Light dregs, mainly from the screening and purification of fibres in the papermaking process, have the characteristics of large volume and low density; while the stranded rope, the production process is the formation of tangles, often containing impurities such as metal wires and other processing difficulties. Crushing of light slag and stranded rope is a key step in resource recovery and reuse. Crushing can effectively reduce the volume of waste, easy to store and transport; at the same time, it can also remove impurities and improve the efficiency and quality of the subsequent treatment process.

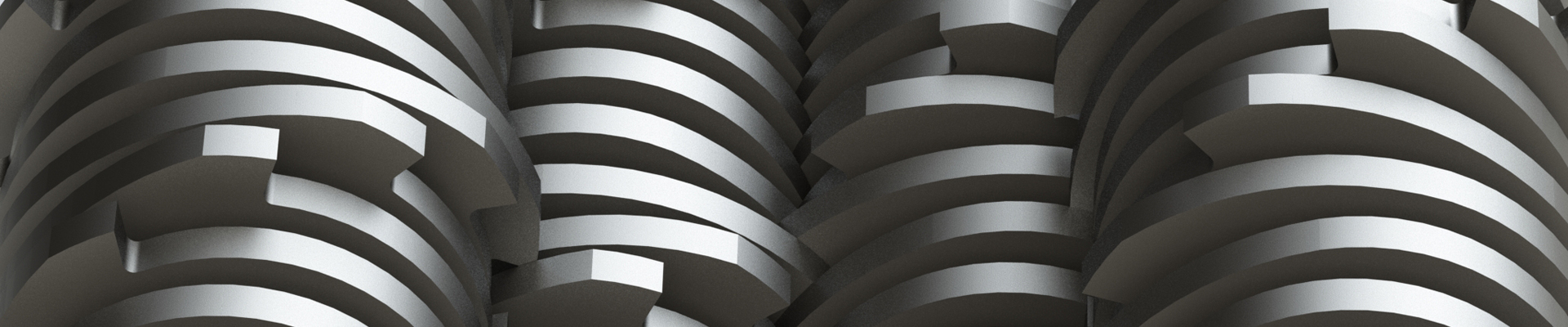

Our paper mill waste shredding system, designed specifically for paper mills, integrates a high-efficiency shredder and a sorting system. The shredder is designed with special knives that can easily cope with a wide range of materials and shapes of waste.